Wine Quality Preservation: How Bag-in-Box Packaging Protects Aroma, Flavor & Color

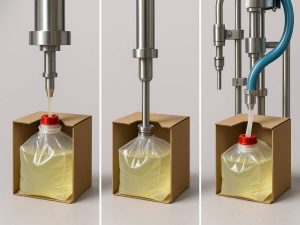

For centuries, wine has been synonymous with glass bottles and corks. Yet, as both environmental awareness and consumer expectations evolve, winemakers are rethinking packaging beyond tradition. Modern consumers want sustainability without compromising taste—and that’s where Bag-in-Box (BIB) wine packaging emerges as a breakthrough. Once seen as merely convenient or budget-friendly, Bag-in-Box technology has become a serious contender in premium wine preservation. By controlling oxygen exposure and shielding wine from light, it extends freshness, aroma, flavor, and color far beyond the limits of traditional bottles. The Science of Wine Deterioration Wine is a delicate, living product. Its taste and appearance are shaped by complex chemical compounds—esters, anthocyanins, phenols, and acids—that react to environmental conditions. The enemies of wine preservation include: Oxygen exposure, which causes oxidation and spoilage. Light, especially UV radiation, triggers photo-oxidation and color loss. Temperature fluctuations, accelerating aging, and degradation. Microbial growth, leading to unwanted odors or haze. In traditional bottles, even the best closures allow trace amounts of oxygen ingress over time. Once opened, oxidation occurs quickly, dulling aroma and turning vibrant reds or whites into flat, brownish liquids. Maintaining wine quality, therefore depends on controlling exposure—and that’s exactly what Bag-in-Box systems are designed to achieve. Oxygen: The Main Enemy of Aroma and Flavor Oxygen is essential in winemaking but disastrous in storage. Controlled oxygen contact during fermentation adds complexity; uncontrolled exposure afterward destroys it. When oxygen reacts with phenolic compounds, it breaks down fruity esters and develops aldehydes, leading to flat, sherry-like off-flavors. Red wines lose color and brightness, while whites darken prematurely. Bag-in-Box packaging addresses this challenge with multilayer barrier films that restrict oxygen ingress to an extremely low level. Combined with a one-way dispensing tap, it ensures air never flows back into the bag after pouring—unlike bottles, where each opening introduces new oxygen. Oxygen Ingress Rates by Packaging Type Packaging Oxygen Transmission Rate (OTR) Shelf Life After Opening Typical Use Case Glass Bottle (Cork) Moderate (through cork pores) 1–3 days Traditional retail Screw Cap Low 5–7 days Premium still wines Bag-in-Box (3 L) Very Low (barrier film sealed tap) 4–6 weeks Everyday & sustainable wines BIB packaging for wine can maintain low oxygen levels not just after opening but throughout the entire shelf life—making it ideal for both home use and on-premise service. How Bag-in-Box Technology Protects Wine Integrity The Bag-in-Box design is deceptively simple but technologically advanced. It includes: An inner flexible bag made from multi-layer plastic film, typically combining polyethylene (PE), ethylene-vinyl alcohol (EVOH), and sometimes metallized PET. An outer cardboard box, which provides structure, insulation, and protection from light. A dispensing tap, which ensures airtight, drip-free pouring. Each component plays a key role. The EVOH barrier prevents oxygen transmission, while the metallized layer reflects UV and visible light that could degrade pigments and flavors. As wine is dispensed, the bag collapses inward—preventing any air pocket from forming. This vacuum effect virtually eliminates headspace, halting oxidation and preserving the wine’s chemical balance. Aroma Preservation: Keeping the Bouquet Intact The pleasure of wine begins