As demand grows for sustainable and efficient liquid packaging, Bag-in-Box (BIB) systems have become a leading solution across industries. From wine to detergents, BIB machines offer precise, low-waste packaging for food and non-food liquids.

Bag-in-Box Packaging: What Is It?

Bag-in-Box packaging consists of a flexible inner bag (made from multi-layer films for barrier protection) and a rigid or semi-rigid outer box (typically corrugated cardboard). The liquid is dispensed via an attached valve or tap. BIB systems are known for:

- Lightweight design

- Low oxygen permeability

- Excellent product protection

- Extended shelf life (even after opening)

Industries favor this packaging not only for its functionality but also for its lower environmental footprint compared to glass or rigid plastic containers.

How Do Bag-in-Box Filling Machines Work?

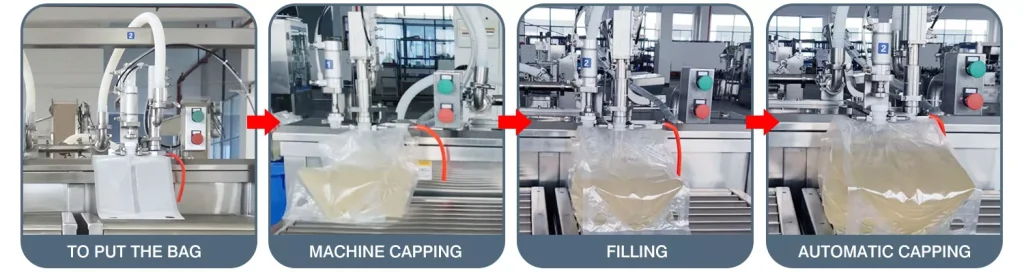

BIB filling machines automate the process of filling and sealing flexible liquid pouches inside protective boxes. While designs vary by industry and speed, most machines perform the following steps:

- Bag Feeding: Pre-made bags are loaded manually or automatically.

- Cap Removal: The machine automatically removes the cap from the spout.

- Vacuuming (optional): Some machines remove air or pre-flush with inert gas (like nitrogen or CO₂) to preserve product integrity.

- Filling: The machine fills the bag with the desired volume, typically using a flow meter or load cell for precision.

- Cap Re-insertion or Crimping: The spout is securely re-sealed.

- Box Insertion (optional): Some systems place the filled bag into the box, seal the flaps, and label the final package.

BIB fillers can be:

- Manual

- Semi-automatic

- Fully automatic

Depending on output needs and integration with existing production lines.

Benefits of Using BIB Filling Machines

A. Maintaining the Quality of the Product

Liquids like wine and juice deteriorate when exposed to oxygen and light, which the BIB system minimizes. Inert gas flushing, vacuum sealing, and airtight caps help preserve freshness and flavor even after opening.

B. Improved Efficiency and Cleanliness

Automated filling machines minimize product spillage, reduce human error, and ensure hygienic handling, especially important for food-grade products like milk or oil.

C. Cost Savings in Packaging and Shipping

- Lower material cost compared to bottles or cans

- Lighter weight means lower shipping costs

- Cube-efficient design for optimal storage

D. Sustainability

BIBs use up to 70% less plastic than rigid containers and are more easily recyclable. They also reduce carbon footprint during transportation due to their space efficiency.

E. Customizable for Various Liquids

Whether thick or thin, acidic or neutral, sterile or non-sterile, BIB machines can be tailored to accommodate different viscosities and temperature requirements.

Industries and Liquids Best Suited for BIB Filling

| Industry | Liquid Products | Why BIB Works Well |

| Beverage | Wine, Juice, Syrups, Cold Brew, Tea | Preserves taste, minimizes oxidation |

| Food | Cooking Oil, Vinegar, Sauces, Dairy | Hygienic, portion-controlled dispensing |

| Chemical | Detergents, Cleaners, Solvents | Safer handling and reduced spillage |

| Pharmaceutical | Nutraceuticals, Liquid Vitamins, Antiseptics | Precise dosing, clean packaging |

| Agricultural | Fertilizers, Pesticides, Animal Health Products | Leak-proof, weather-resistant storage |

Types of Bag-in-Box Filling Machines

A. Manual BIB Fillers

- Operated by hand

- Low cost and compact

- Ideal for startups or small batches

B. Semi-Automatic Fillers

- Automated fill cycles, manual bag feeding

- Good for medium-sized operations

- Balance between cost and output

C. Fully Automatic Fillers

- Continuous high-speed operation

- Integrated with box forming, labeling, and sealing

- Suitable for high-volume producers

D. Aseptic Fillers

- Designed for sterile filling of sensitive liquids (e.g., dairy, juice)

- Include sterilization stages and cleanroom-compatible parts

E. Hot Fill Systems

- Used for sauces or syrups filled at high temperatures

- Equipped with heat-resistant components and cooling zones

Key Features to Look for in a BIB Filling Machine

When selecting a machine for your specific product, consider:

- Filling Accuracy: Load cells or magnetic flow meters for precise volume control.

- For simple and sanitary cleaning in between batches, use the Clean-in-Place (CIP) system.

- Spout Compatibility: Ability to handle different cap sizes, types, and brands.

- Bag and Box Size Flexibility: Adaptable to different volumes from 1L to 20L+.

- Speed and Throughput: Matches your daily production requirements.

- Control Interface: User-friendly HMI for monitoring and diagnostics.

- Sterility Assurance: For sensitive products like milk or juice, aseptic options are critical.

Operational Workflow in a BIB Filling Line

Here’s a simplified layout of a typical BIB production line:

- Uncasing & Bag Unfolding

- Spout Decapping

- Nitrogen Flushing (optional)

- Filling via Pump or Gravity

- Spout Recapping

- Leak Testing (optional)

- Box Insertion & Sealing

- Labeling & Palletizing

Automation at each of these stages boosts speed and ensures product safety from bag to box.

Case Study: Wine Packaging with BIB Systems

The wine industry has embraced Bag-in-Box packaging not just for its cost savings, but also for preserving wine quality post-opening.

Benefits include:

- Prevents oxygen ingress during repeated pouring

- Easier logistics for restaurants and caterers

- Consistent serving volumes

- Lower breakage risk during shipping

Wineries using automatic BIB filling lines report 25–40% savings compared to traditional glass bottling, without compromising on flavor.

BIB Filling Machines vs. Other Filling Technologies

| Feature | BIB Filling Machine | Bottle Filling | Pouch Filling |

| Container Cost | Low | High | Medium |

| Oxygen Exposure | Minimal | Higher | Depends on the cap design |

| Filling Speed | Medium to High | High | Medium |

| Environmental Impact | Low | High | Medium |

| Dispensing Convenience | High (integrated tap) | Medium | Medium |

| Best for Bulk Packaging | Yes | No | Partial |

For companies aiming to ship or store liquids efficiently while retaining quality, BIB clearly has the edge.

Maintenance and Care of BIB Machines

Like any industrial equipment, regular maintenance ensures long-term performance:

- Routine sanitization of product-contact surfaces

- Lubrication of moving mechanical parts

- Periodic calibration of sensors and valves

- Inspection of seals, gaskets, and nozzles

- Software updates (for advanced control systems)

Ensure your supplier provides after-sales support and easy access to replacement parts.

Sustainability Benefits of BIB Machines

Sustainability is increasingly driving packaging choices. BIB solutions reduce:

- Packaging waste (less plastic, less weight)

- Carbon footprint (better pallet density)

- Energy use in both production and transport

Additionally, many bags are made from recyclable films and boxes from FSC-certified cardboard, aligning with circular economy goals.

Bag-in-Box filling machines have transformed liquid packaging with their purity, efficiency, and sustainability. Suitable for everything from wine to oil, they support small producers and large manufacturers alike. Choosing the right manual, semi-automatic, or automatic system depends on your needs—but Bag-in-Box is already setting the new standard in liquid packaging.