The Future of the B2B Food Sector (with Bag-in-Box Insights)

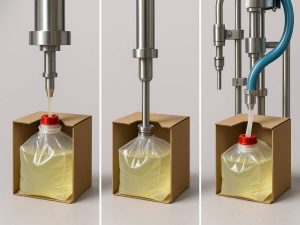

Sustainability has evolved from a marketing claim to a strict business requirement in the global food industry. Brands, distributors, foodservice operators, and ingredient suppliers now face pressure to cut waste, lower carbon footprints, and meet rapidly changing regulations on plastics and recycling. Packaging sits at the center of this shift, shaping both environmental performance and compliance. In the high-volume, complex B2B food sector, packaging choices can significantly impact costs, sustainability goals, and supply-chain efficiency. From bag-in-box and lightweight pouches to reusable systems and digital traceability, new formats are transforming how food is packed, shipped, and dispensed. This article highlights the key trends driving sustainable food packaging and how they are reshaping the future of B2B supply chains. Why Sustainable Packaging Matters More in B2B Than Ever Several forces are driving rapid change in B2B food packaging: Stricter regulations on single-use plastics and extended producer responsibility (EPR). Many regions are introducing producer fees, recyclability requirements, and bans on certain formats such as non-recyclable multilayer films or expanded polystyrene. Corporate sustainability commitments. Large retailers, QSR chains, and ingredient manufacturers have published aggressive packaging goals (recyclable/compostable/reusable by 2025–2030, percentage of recycled content, etc.), pulling suppliers along their value chain. Cost and risk management. Waste disposal costs, volatility in virgin resin prices, and reputation risks around plastic pollution incentivize more resource-efficient packaging systems. Customer expectations. Foodservice operators and industry buyers increasingly prefer packaging that reduces storage space, simplifies handling, and demonstrates environmental responsibility. In B2B, packaging is often larger format, higher volume, and more functionally demanding than consumer retail packs. That makes sustainable innovation especially impactful: a small design change on a 10–20 L container can save tons of material and transport emissions across a year. Lightweighting and Material Reduction One of the most immediate sustainability wins is using less material per unit of product. Key strategies Thinner films and optimized structure Advances in polymer science and co-extrusion allow converters to maintain barrier performance while cutting film thickness. For bulk sauces, concentrates, and dairy ingredients, this can shave grams off every bag or liner. Structural redesign for strength Ribbed walls, gussets, and load-bearing corners can keep large containers stable with less plastic. Palletization simulations help minimize over-engineering. Right-sizing for B2B portions Instead of one universal 20 L format, suppliers are introducing 8 L, 10 L, or 15 L sizes tailored to usage rates in restaurants, catering, or industrial kitchens. Less product goes out of date, and packaging isn’t wasted on overfilled formats. Lightweighting must be balanced with durability: in B2B logistics, failures are costly, causing food waste and contamination risks. This is one area where bag-in-box (BIB) systems excel—they use minimal plastic in flexible bags while relying on a strong outer carton for stacking and transport performance. The Rise of Bag-in-Box Systems in B2B Food Bag-in-box packaging has become one of the most important formats in the sustainable B2B toolbox, especially for liquids and semi-liquids such as: Juices, wines, and beverage syrups Dairy products and UHT milk Edible oils and sauces Ready-to-drink mixes and post-mix concentrates How Bag-in-Box Works