Product Information:

Our flowmeter-based bag-in-box filling machine (with its own power supply) is suitable for quantitative filling of liquid flexible packaging bags. It features temperature-tracking density compensation technology, automatically compensating for errors caused by density changes due to temperature fluctuations.

It offers flexible switching between mass and volumetric filling modes (filling can be performed based on the displayed kilograms or milliliters). It features fast and slow filling speeds to prevent spillage. Vacuum suction eliminates dripping.

The Siemens PLC ensures stable and reliable operation. The Siemens touchscreen human-machine interface makes operation simple. Capping, filling, and capping are all completed automatically.

The liquid delivery method is pumped, eliminating the need for a high-pressure tank to provide a pressure drop. Because the two filling heads have separate control systems, a malfunction in one won’t interfere with the other’s regular operation.

On-site verification with actual liquid is available, allowing users to check filling accuracy. Our filling machine can adjust errors promptly.

Filling System:

The filling equipment can be combined with a fully automatic carton sealing machine, a fully automatic film wrapping machine, and a heat shrink machine to form an integrated filling, sealing, and film wrapping production line.

Working Line:

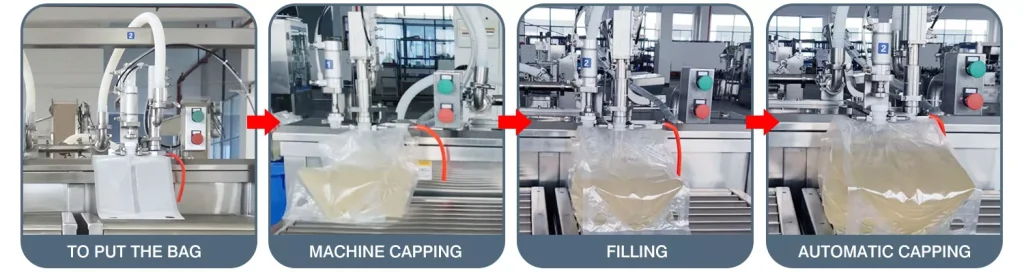

The working procedure of BIB filling machine is to put the bag on the machine →, → automatically cap → automatically cap → put the bag in again for the next filling.