Flexible liquid packaging solutions are transforming how industries handle, store, and distribute liquid products. From food and beverage to chemicals and personal care, flexible formats—such as pouches, bags, cubitainers, liners, and sachets—offer benefits that rigid containers struggle to match. With shifts toward sustainability, digitalization, and cost optimization, flexible liquid packaging is poised for continued growth.

What Is Flexible Liquid Packaging?

Flexible liquid packaging refers to non-rigid containers designed to hold liquids. Unlike bottles, drums, or cans, flexible packaging can change shape depending on contents, allowing efficient storage and transport.

Common examples include:

- Stand-up pouches

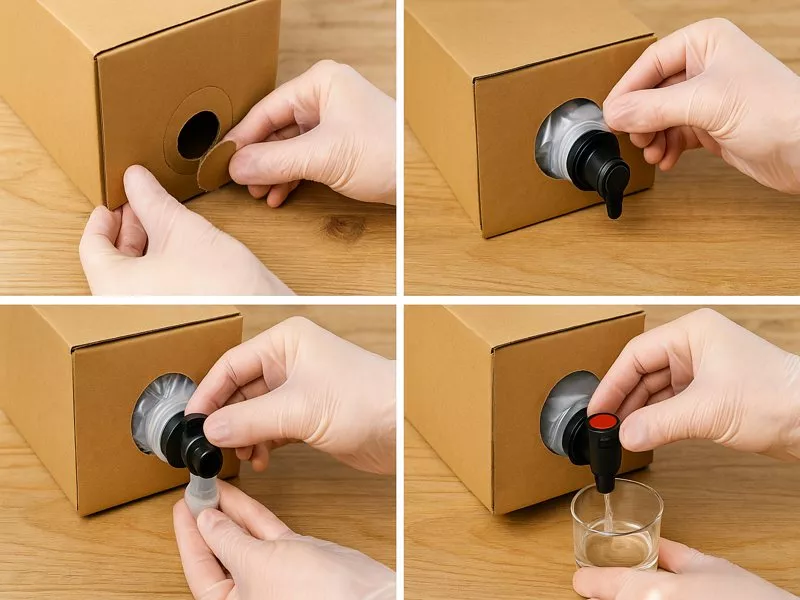

- Bags-in-boxes

- Cubitainers

- Liners and bladders

- Sachets and small dosage packs

These formats use materials like multilayer films, plastic laminates, foil, and polyethylene blends to balance barrier performance, strength, and cost.

Market Drivers for Flexible Liquid Packaging

Several macro forces are fueling the adoption of flexible liquid packaging solutions:

Sustainability Imperatives

Environmental concerns are pushing companies to reduce packaging waste, lower emissions, and shift to recyclable or lightweight materials.

Cost Optimization

Flexible packaging often costs less than rigid alternatives in terms of materials, transportation, and storage space—especially for large volumes.

Consumer Convenience

Formats like stand-up pouches and sachets enhance usability, portion control, and on-the-go consumption.

Supply Chain Efficiency

Flexible solutions can reduce weight, improve pallet utilization, and enable decentralized filling.

Key Advantages of Flexible Liquid Packaging

| Advantage | Impact |

| Lightweight Materials | Lower transport emissions & costs |

| Space-Efficient Shapes | Higher warehouse & pallet utilization |

| Lower Material Use | Reduced packaging waste |

| Versatile Formats | Multiple industry applications |

| Customizable Design | Enhanced branding & differentiation |

Trend #1: Sustainability and Circular Materials

Sustainability is the most dominant trend in flexible liquid packaging. Companies are reshaping their designs to meet regulatory pressures and consumer expectations.

Lightweighting

Reducing material weight lowers carbon emissions and transport costs. Flexible formats inherently use less packaging material than rigid containers.

Recyclable and Mono-Material Films

Traditionally, flexible packaging used multiple layers that were hard to recycle. New mono-material solutions (e.g., polyethylene-only films) improve recyclability without compromising performance.

Refill and Reuse Models

Refill stations for liquid products—such as detergents or food sauces—allow consumers to reuse flexible pouches or containers, reducing single-use waste.

Sustainable Material Innovations in Flexible Liquid Packaging

| Innovation | Sustainability Benefits | Challenges |

| Mono-material Films | Simplified recycling | Performance trade-offs |

| Biodegradable Polymers | Reduced landfill impact | Cost & infrastructure gap |

| Refillable Pouches | Less single-use waste | Requires a consumer behavior shift |

| Recycled Content Films | Lower carbon footprint | Quality consistency |

Trend #2: Digital and Smart Packaging

Digital technologies are adding new dimensions to flexible liquid packaging:

QR Codes and Traceability

Scanning a QR code on a pouch can provide product origin, batch history, and expiration data—critical for food, pharmaceuticals, and industrial liquids.

RFID and IoT Sensors

Tags embedded in packaging enable real-time tracking during distribution, improving inventory management and reducing loss.

Anti-Counterfeiting Measures

Security features like digital watermarks help protect high-value liquids such as chemicals, cosmetics, and pharmaceuticals.

Digital Features in Flexible Packaging and Their Uses

| Digital Feature | Primary Use Cases |

| QR Codes | Consumer information & traceability |

| RFID Tags | Supply chain visibility |

| NFC Integration | Interactive marketing |

| IoT Sensors | Real-time condition monitoring |

| Blockchain Integration | Authenticity & provenance |

Trend #3: Customization and Brand Differentiation

Flexible liquid packaging has become a branding tool. Advances in printing and design allow vibrant graphics and form factors tailored to consumer preferences.

- Die-cut windows for product visibility

- Ergonomic designs for easy pouring

- UV printing for premium aesthetics

- Limited edition or seasonal packs

Brands can rapidly prototype and iterate designs, enhancing engagement.

Trend #4: Efficiency in Food, Beverage & Personal Care Markets

Flexible liquid packaging is increasingly used for:

- Beverages (juice, water, dairy)

- Sauces and condiments

- Liquid detergents and cleaners

- Skincare and cosmetics

Consumers appreciate convenience formats like spouted pouches, sachets, and stand-up bags for their portability and ease of use.

Example:

A spouted pouch for liquid soap offers controlled dispensing and occupies less shelf space than a rigid bottle.

Trend #5: Increased Adoption in Industrial & Agricultural Sectors

Flexible solutions are no longer confined to consumer goods. Industrial and agricultural sectors are adopting formats such as:

- Cubitainers for chemicals and lubricants

- Liners for IBCs and drums

- Bladder systems for field dispensing

These formats streamline bulk handling while reducing transportation weight and storage footprint.

Trend #6: E-Commerce and Direct-to-Consumer Packaging

The rise of e-commerce has accelerated demand for packaging that can endure transit stress while minimizing damage and returns.

Flexible packaging advantages for e-commerce include:

- Better protection in poly-bags or mailers

- Lower shipping weight

- Compact storage for fulfillment centers

Brands are designing packaging that performs well in supply chains and resonates with online shoppers.

Table 4: Flexible Packaging Formats and Typical Applications

| Packaging Format | Typical Use Industries | Why It’s Preferred |

| Stand-up Pouches | Food & Beverage, Personal Care | Shelf appeal & convenience |

| Spouted Pouches | Beverages, Detergents | Controlled pouring & reuse |

| Sachets | Pharmaceuticals, Samples | Portioning & trials |

| Cubitainers | Industrial liquids, Agrochemicals | Space & handling efficiency |

| Bag-in-Box | Beverages, Ingredients | Large volume & reduced waste |

| Liners & Bladders | Bulk transport | Contamination control |

Manufacturing & Supply Chain Trends

Near-shoring and Regionalized Production

To reduce lead times and risk, companies are decentralizing packaging production closer to end markets.

Automation of Filling and Sealing

Advances in automation lines improve throughput and reduce contamination risk, especially for sensitive liquids.

Collaborative Supplier Ecosystems

Packaging suppliers, resin producers, and converters are working together to optimize materials, supply continuity, and performance.

Regulatory and Safety Considerations

Flexible liquid packaging must comply with regulatory standards depending on the application:

- Food-contact certification (FDA, EU standards)

- UN marking for hazardous liquids

- Child-resistant and tamper-evident closures

- Labeling requirements (GHS, nutritional info, instructions)

As regulations evolve, packaging designs must meet safety, traceability, and environmental mandates.

Challenges Facing Flexible Packaging

Despite rapid growth, flexible liquid packaging has challenges:

Recycling Infrastructure Gaps

Many regions lack facilities for processing flexible films, limiting circularity.

Material Performance Trade-offs

Balancing barrier properties with recyclability can be complex.

Consumer Perceptions

Some users still prefer rigid packaging for perceived durability or a premium feel.

Cost of Innovation

New materials and digital features can increase unit costs, especially for small runs.

Future Outlook: What Comes Next?

The next decade will likely see:

Greater Adoption of Recyclable & Bio-Based Polymers

Breakthroughs in material science are expected to deliver high-performance, fully recyclable films.

Enhanced Digital Engagement

Packaging will become a digital touchpoint offering personalized information, loyalty features, and real-time tracking.

Circular Economy Models

Manufacturers will increasingly adopt reuse schemes, refill stations, and take-back programs.

Sustainable Supply Chain Integration

Flexible packaging choices will be part of broader sustainability strategies for water use, emissions, and end-of-life disposal.

Future Trends in Flexible Liquid Packaging Solutions

| Trend | Expected Impact | Timeline |

| Fully recyclable mono-materials | Higher recovery & reuse | Short-to-mid term |

| Smart packaging & IoT integration | Better traceability & consumer engagement | Mid term |

| Refillable packaging systems | Reduces single-use consumption | Mid-to-long term |

| Circular supply chain partnerships | Lower environmental footprint | Long term |

Flexible liquid packaging is no longer a niche solution—it is a strategic enabler across industries. Driven by sustainability demands, digital transformation, and changing consumer expectations, flexible formats are reshaping how liquids are packaged, transported, and consumed.

From stand-up pouches and spouted bags to cubitainers and bag-in-box systems, flexible packaging offers:

- Reduced material and transport costs

- Improved space utilization

- Enhanced consumer convenience

- Support for traceability and safety

However, challenges such as recycling infrastructure and material performance remain critical areas for innovation.

Looking forward, flexible liquid packaging will continue to evolve—driven by material science breakthroughs, consumer behavior shifts, and regulatory momentum toward circularity and environmental stewardship.

For manufacturers, brands, and packaging professionals, staying ahead of these trends is not just a competitive advantage—it’s a business imperative.