Oxygen barrier effect of bag-in-box cheertainer packaging. The gas blocking function is the main factor affecting the quality of the product during the shelf life, and it is also the main reference for analyzing the shelf life. If the gas barrier function of the packaging material is poor, it will cause problems such as oxidative degradation of the content due to its sensitivity to oxygen. The gas barrier function is measured by the gas transmission rate of the material, and the relevant specifications clearly stipulate that the gas transmission rate of plastic films and sheets is tested by the differential pressure method. Of course, after ensuring that the air resistance function, sealing function and bottle cap torque target of the bag-in-box cheertainer packaging are qualified, other targets such as sealing strength and stretching function need to be controlled to ensure the shelf life of the product and the adaptability to use.

The sealing function refers to the reliability of the bag-in-box cheertainer packaging. This test can ensure the integrity of the entire product packaging and prevent leakage, pollution, and deterioration due to poor product sealing performance. There are many ways to test the sealing performance. The most commonly used method is to use a sealing tester. For vacuum packaging, it is mainly to investigate the recovery status of the sample after the test. Of course, the above method is based on the principle of visual inspection, which is a qualitative test method. If you want to quantitatively check the sealing and leakage performance of packaging and packaging, you can use positive pressure method principle sealing performance testing equipment, leakage and sealing strength tester.

The bag-in-box cubitaine is more advertising effect: a beautiful bag-in-box cubitaine is more than just a packaging bag for a product. Its exquisite appearance is even more addictive, and it can be transformed into a stylish and concise shoulder bag and become a beautiful scene on the street. Coupled with its solid, waterproof and non-stick properties, it will definitely become the top choice for customers to go out. On such a bag-in-box cubitaine, you can print your company's symbol or advertisement, and the advertising effect it brings is obvious. , the real small investment into a big return.

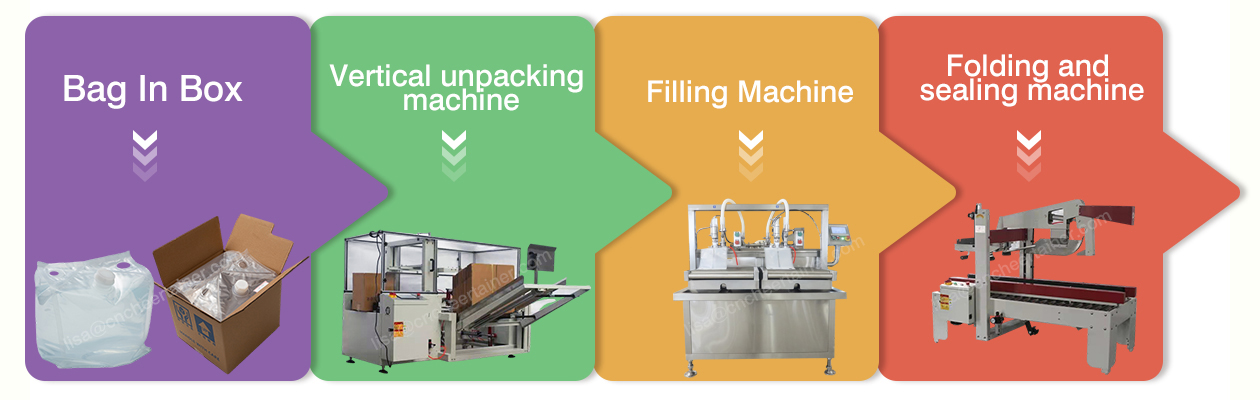

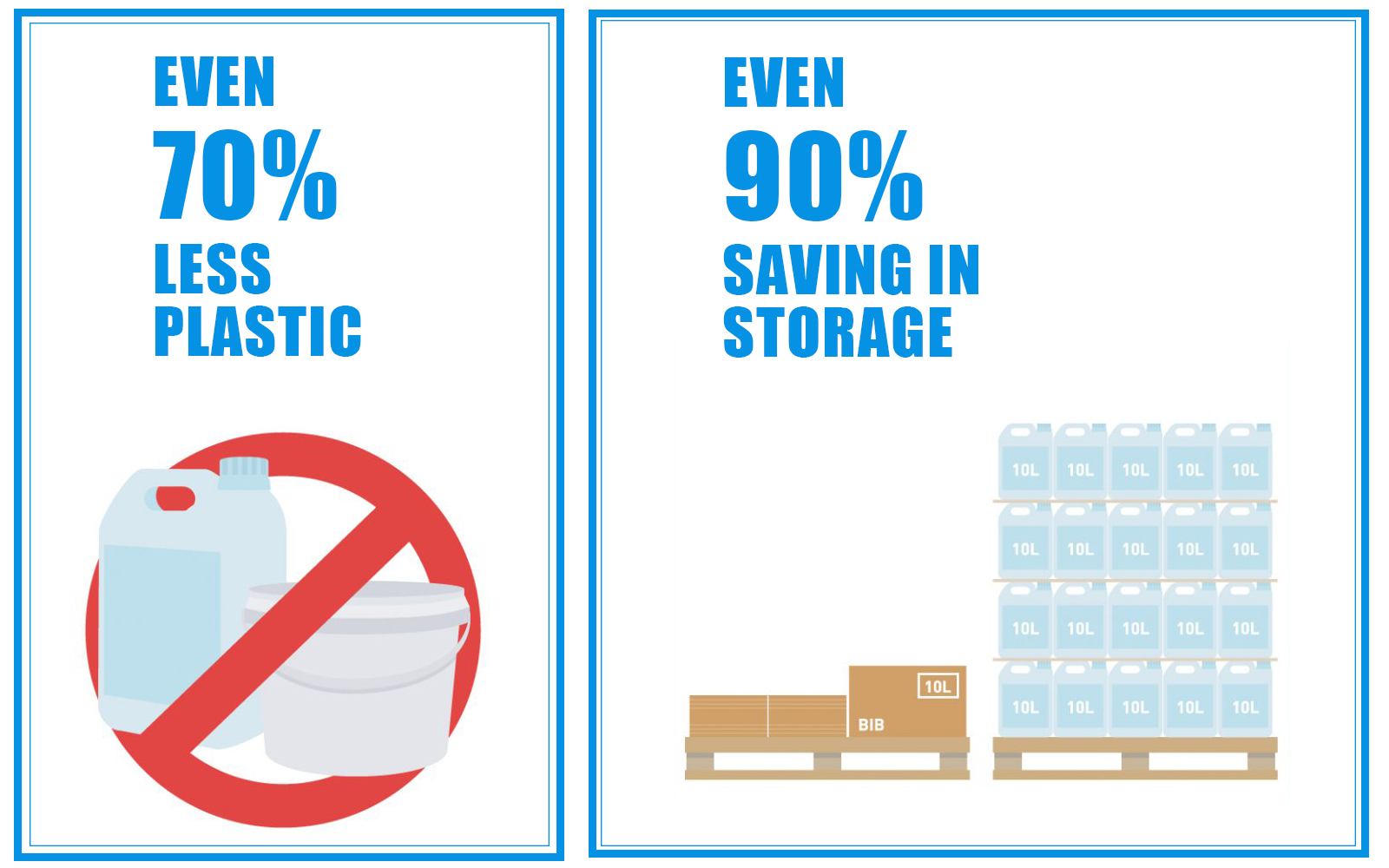

Compared with traditional packaging methods, bag-in-box cubitaine packaging has very significant competitive advantages, such as longer shelf life, very good light and oxygen barrier properties, using very little material and being recyclable. A variety of standard commodities are processed on the filling equipment, which can be suitable for aseptic/non-aseptic/cold filling/hot filling/various processing processes, from semi-automatic to fully automatic filling equipment for flexible selection, improving storage and Shipping efficiency, reduced storage and shipping costs, significantly reduced packaging costs, etc. Now, the bag-in-box cubitaine packaging method is widely used in fruit juice, wine, fruit juice drinks, mineral water, edible oil, food additives, industrial pharmaceuticals, medical reagents, liquid fertilizers, pesticides, etc.

Post time: Jan-17-2022